High temperature biaxial stretching Stretching Machines High-Temperature Successive Biaxial Stretching Machine

High temperature biaxial

stretching

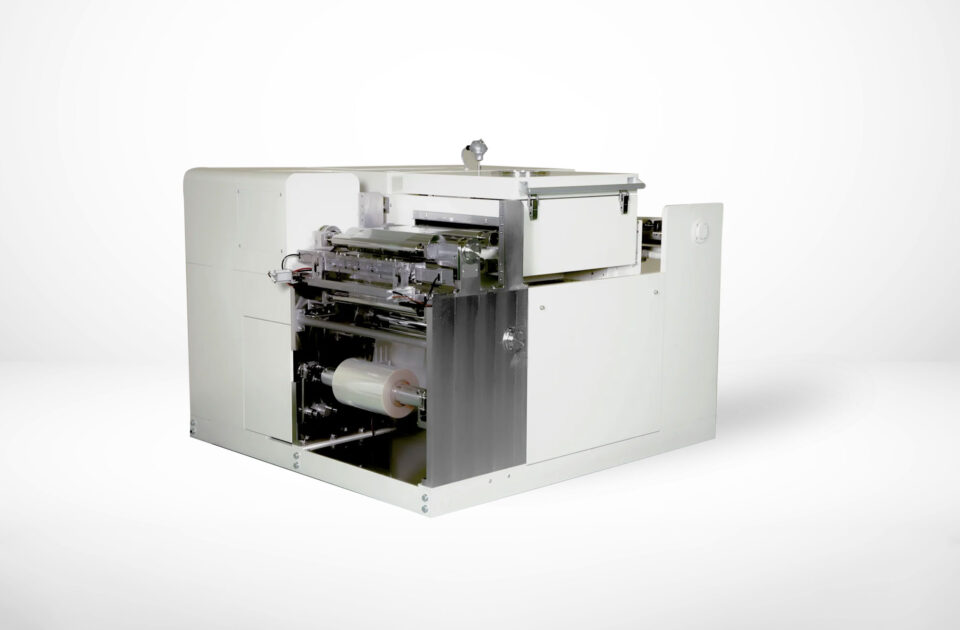

This is a test machine for continuous vertical and horizontal stretching.

It can meet all stretching test requirements, including heat resistance, orientation, and toughness, which are needed for next-generation materials.

Specifications

- Temperature

- (MD)max. 400ºC (TD)max. 400ºC

- Magnification

- (MD) max. 16 times, (TD) max. 15 times

- Speed

- 0.1 to 16 m/min

- Substrate width

- (MD) max. 300 mm, (TD) Inlet 80 to 600 mm, Outlet 300 to 1200 mm

-

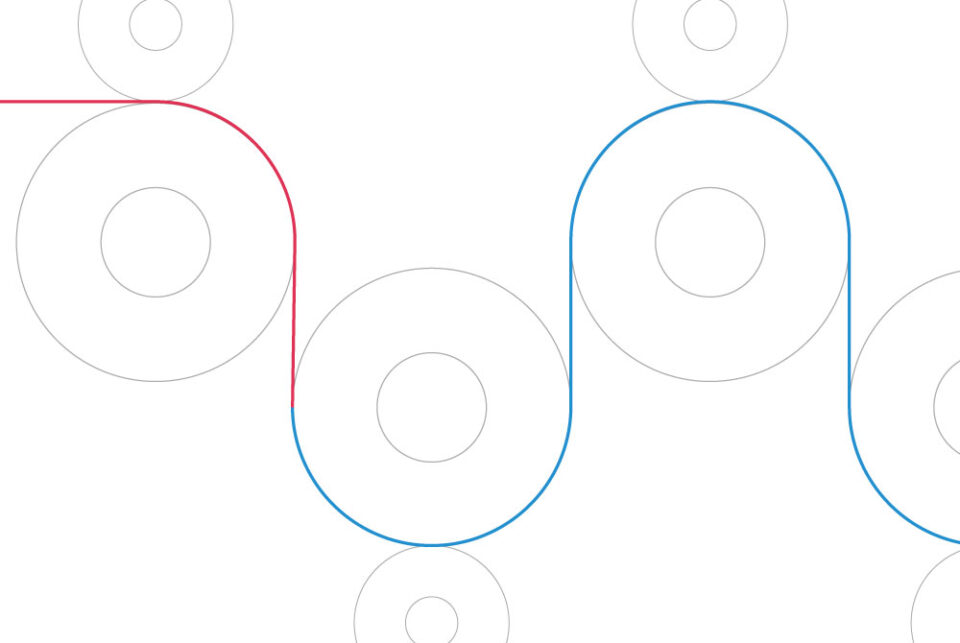

One-step roll stretching

-

Two-step roll stretching

-

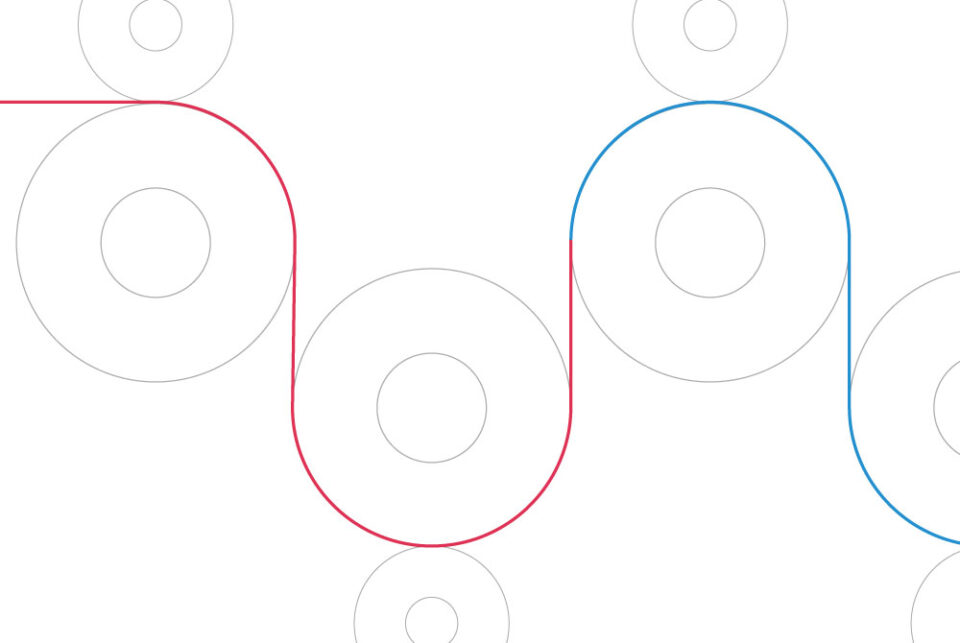

Hot air floating stretching

-

High temperature stretching

-

Heat-setting

-

Stretching and heat-setting

A high-temperature model for handling all types of materials!

It can be heated up to 400°C in both vertical and horizontal stretching.

It is suitable for high-melting-point materials such as PTFE, PI, LCP, and PEEK.

Of course, it can also stretch low-melting-point materials such as PS, PE, PET, and PP.

All settings can be input via tablet. Rail width can also be easily set!

Settings can be input through a tablet via Wi-Fi.

All values are monitored and managed centrally.

Even changing the width of the tenter is fully automated, making it easy for anyone to change it.

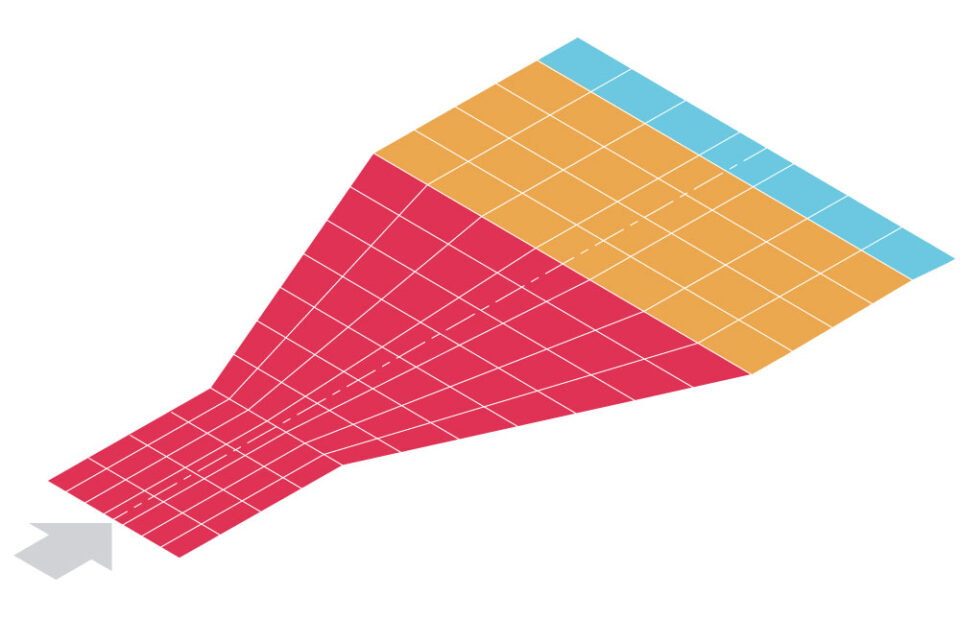

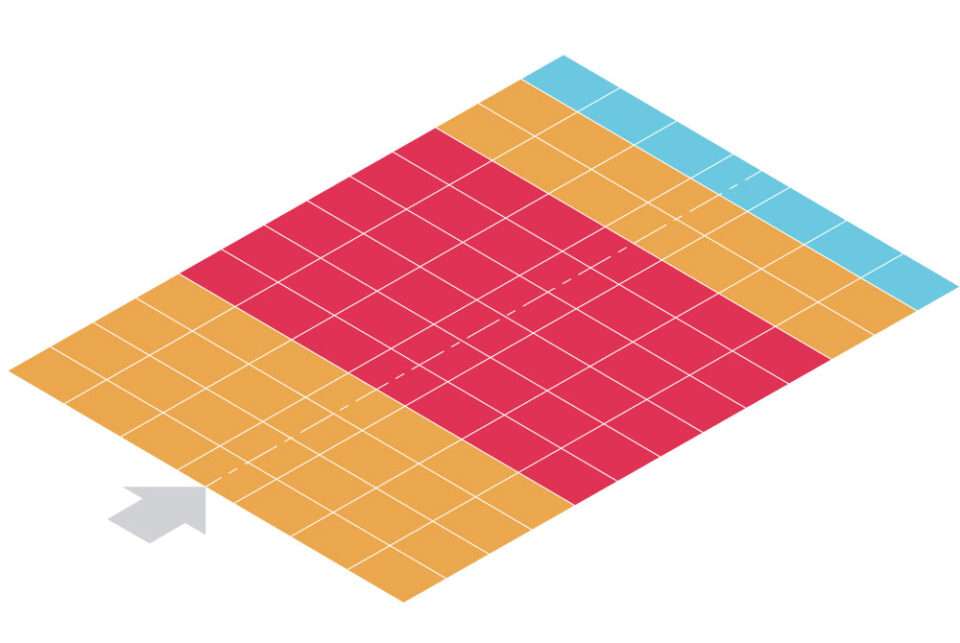

Flexible rail width settings. A wide range of pattern settings is available!

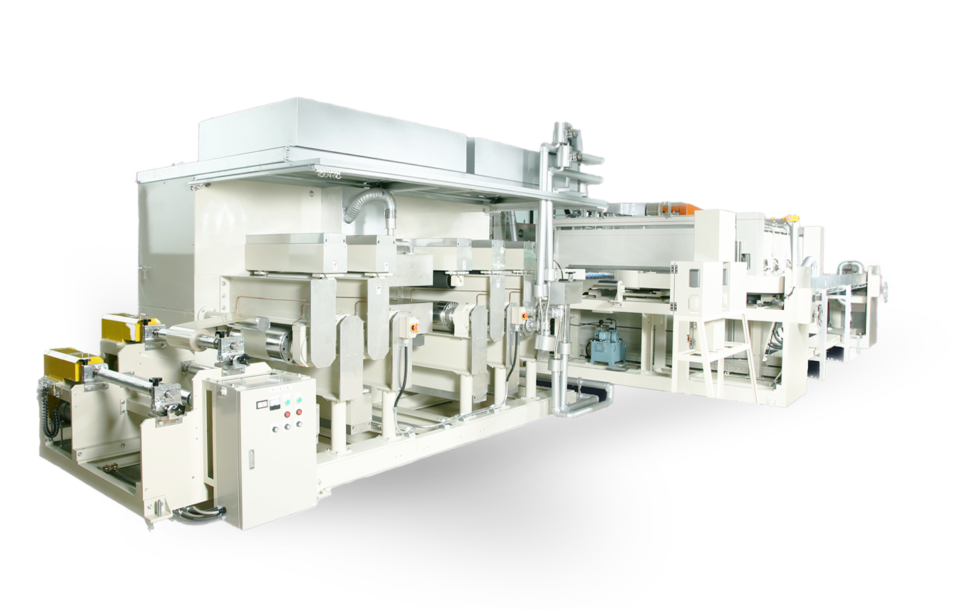

The furnace is composed of five chambers, all with the same structure.

Various stretching patterns can be set, such as rapid stretching in one chamber, gradual stretching over three chambers, and changing the stretching zone.

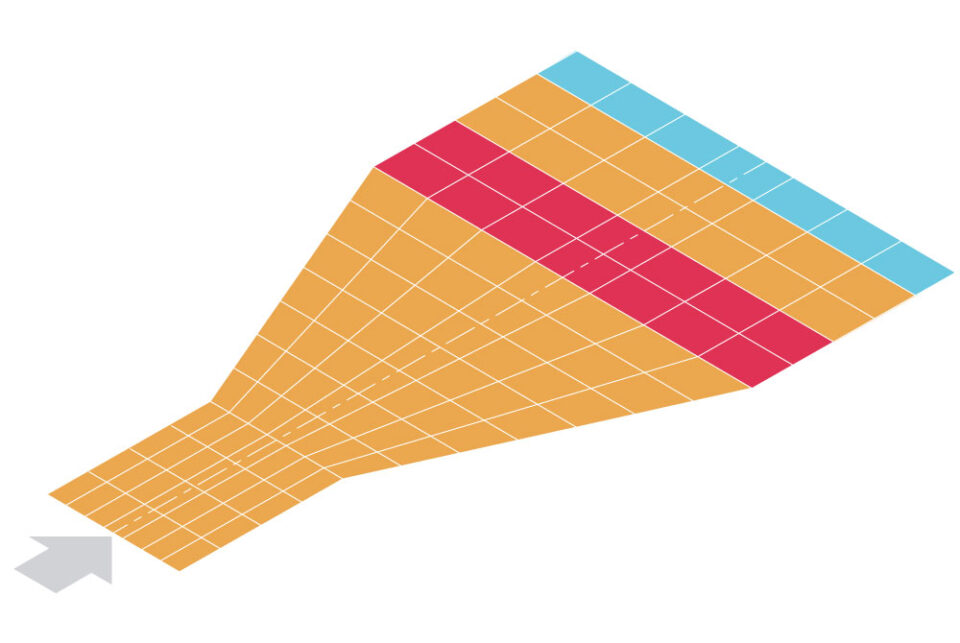

The horizontal stretcher maintains temperature accuracy with a unique circulation system!

The horizontal stretcher adopts an unprecedented circulation system that integrates intake and exhaust, uniformly controlling the temperature accuracy within the furnace.

With a wide range of specifications, it can meet all testing requirements!

The wide specification range allows extensive test coverage, from batch tests with small amounts of base material to full product winding from unwinding to take-up.

ICHIKIN Technical CenterICHIKIN Technical Center

We make the most use of our technology and experience as coating and stretching professionals to meat your needs.

ICHIKIN Technical Center" width="960" height="640" loading="lazy">

ICHIKIN Technical Center" width="960" height="640" loading="lazy">