Specialty ICHIKIN’s Areas of Expertise

No matter how difficult the request or challenge, we will respond flexibly.

Our technology controls the essential elements of heat, wind, and water in film processing.

The techniques and expertise we have developed over many years are widely utilized in the cutting-edge field of polymer chemistry.

New materials of the future are born from small thoughts like "I wonder if this would be possible?"

At Ichikin, we address even the smallest challenges, from basic tests to sample creation, with a focus on testing at our Technical Center!

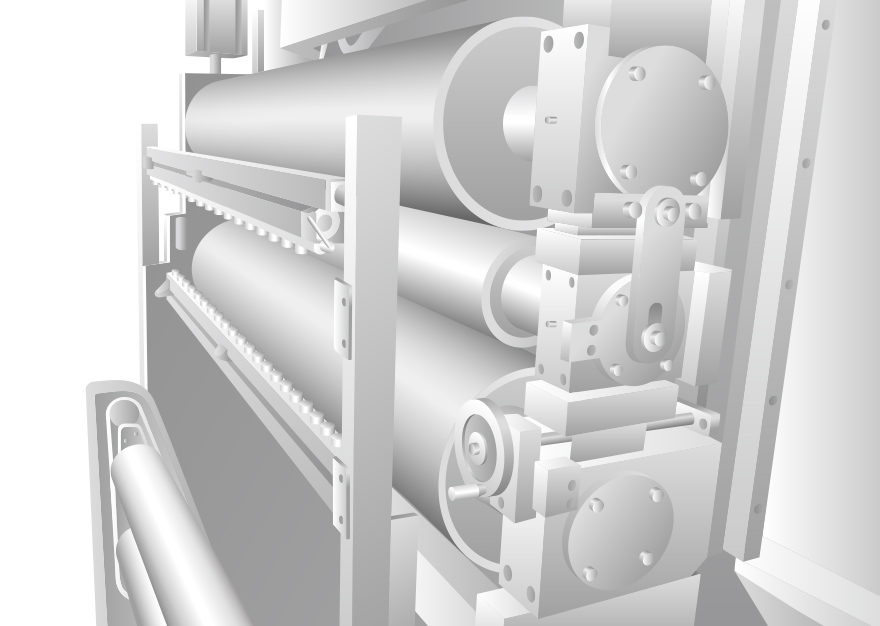

Coating and Hardening

Coating equipment can be utilized to apply resin solutions to materials.

With regard to functional materials, as the demand for thin, uniform, and high-speed coatings increases, the coating method varies widely depending on the composition of the liquid.

Due to the variety of coating conditions, such as viscosity, solid content, thixotropy, and thickness, it is often necessary to conduct repeated experiments to verify the process.

At our Technical Center, we have coating test equipment available to conduct verifications with our customers and propose appropriate coating methods.

- Applications

- LCD film, battery electrodes and separators, high-performance filters, electronic materials

- Methods

- Die, pipe, bar, roll reverse, impregnation

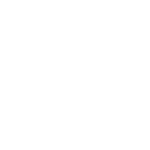

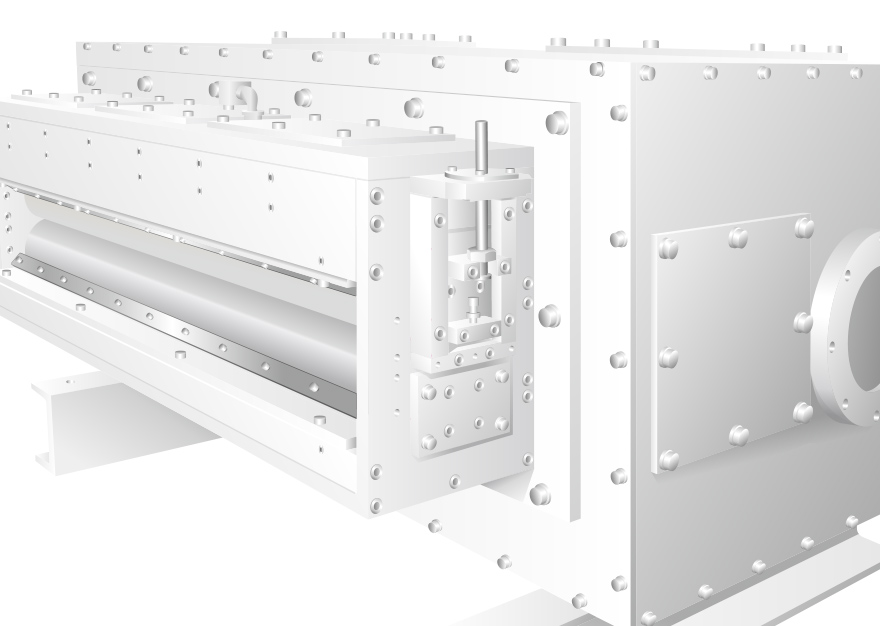

Stretching and Shrinking

Stretching equipment can be used to impart strength and orientation to materials.

In fields such as automotive, battery, and energy, where harsh usage environments are expected, heat resistance, thinness, and increased strength are essential, leading to a growing demand for stretching.

Due to the variety of substrate types and glass transition temperatures, precise temperature settings, stretching ratios, and pulling speeds are crucial, with conditions varying widely.

At our Technical Center, we have test equipment for sequential and simultaneous stretching, allowing us to conduct verifications with our customers and propose appropriate stretching methods.

- Applications

- LCD film, battery separators, high-performance filters, electronic materials, flexible display film

- Methods

- Sequential biaxial stretching (vertical and horizontal), simultaneous biaxial stretching (vertical, horizontal, and shrinkage), high-temperature stretching

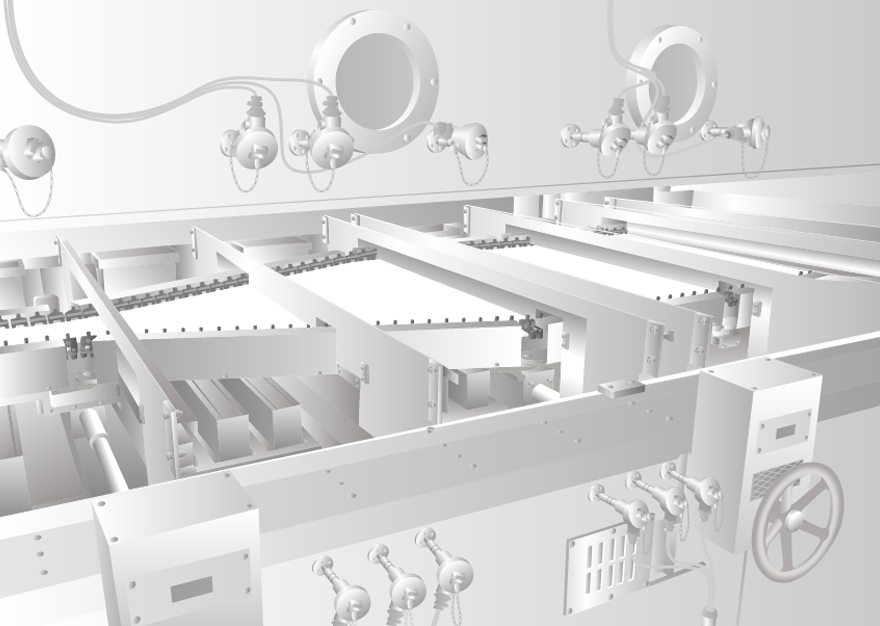

Baking and Drying

Materials can be dried and heat-treated.

Although this process is required for almost all material processing, drying methods vary depending on the type of substrate and liquid.

Thin films require precise temperature control. Thick films need functionality that ensures uniform heating to the core and prevents surface cracking.

Thin substrates or those prone to wrinkling are dried using a floating method. Substrates immersed in liquid or coated on both sides are dried using vertical drying equipment, which can be as tall as a three-story building.

With our solid experience and simulations, we can propose the optimal drying method.

- Applications

- Coating, laminating, dry stretching and heat treatment after liquid processing

- Methods

- Hot air, infrared

Applying and Peeling

Materials can be laminated.

From cutting-edge communication materials like 5G and 6G to the energy sector, multiple materials are laminated together in the final products. Materials have various characteristics: some stretch, some shrink, some are uneven, and some are prone to wrinkling, resulting in a wide range of bonding methods.

Based on our experience with batteries and flat displays, we can propose appropriate laminating methods.

- Applications

- Flexible electronic substrates (PI, LCP, PTFE), LCD film (PVA, TAC, COP), battery components (copper foil, polyimide, LCP, PTFE)

- Methods

- Thermal lamination, adhesive lamination (water-based, solvent-based, UV-based)

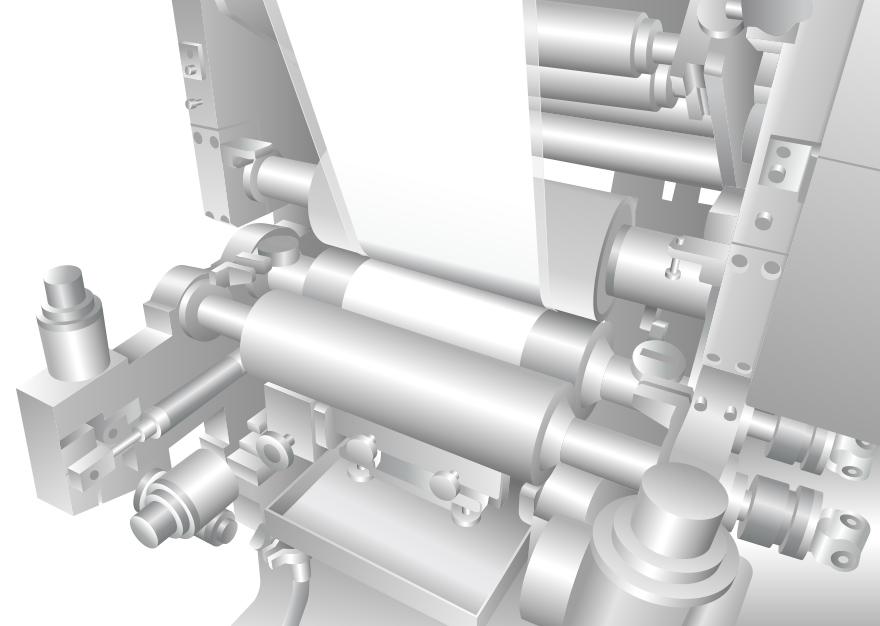

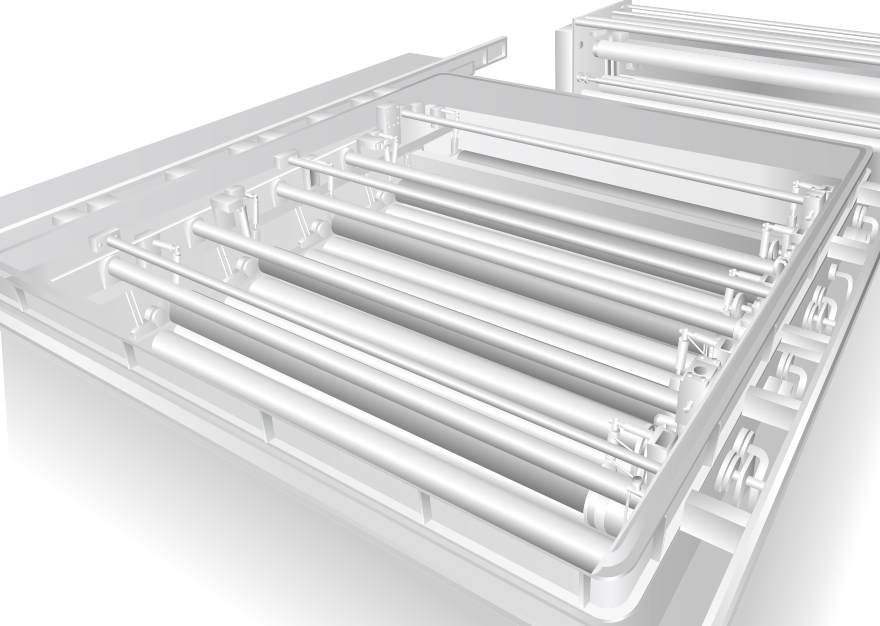

Dipping and Washing

Materials can be impregnated with chemical solutions.

Our company started with the manufacturing and sales of textile dyeing and finishing machines, and the techniques we developed for impregnating, washing, and wringing have been applied to cutting-edge polymer films.

When using acids, alkalis, or solvents, the material, shape, and sealed structure of the tank become crucial.

We propose the optimal liquid processing methods for all processes, including impregnation, dyeing, extraction, washing, and rinsing.

- Applications

- Dyeing and stretching processes for LCD PVA films, extraction processes for lithium-ion battery wet separators, coagulation processes for polymer membranes, impregnation processes for various materials

- Methods

- Impregnation, dyeing, washing

Sealing and Replacing

Materials can be processed while managing the furnace atmosphere.

During material processing, solvent treatment requires oxidation prevention, inertization, and concentration control.

We propose furnace structures suitable for vacuum, nitrogen, and inert gas purging, along with entrance and exit seal structures, and conveying and drying methods.

- Applications

- Oxidation prevention during solvent drying, inertization of explosive solvents, sealing of organic solvents

- Methods

- Vacuum, nitrogen purging, gas concentration control

Inquire About Other Services

Are you dealing with other challenges?

- Stretching material in various directions other than vertical and horizontal.

- Refusal by other manufacturers due to base material contaminating the equipment.

- No equipment inquiry, but would like to conduct a basic experiment.

- No suitable test machine but requiring modification of a demo machine.

- Wondering if it is possible to process a non-film material.

- Want to work on a project in secret.