Coating Coating Machines

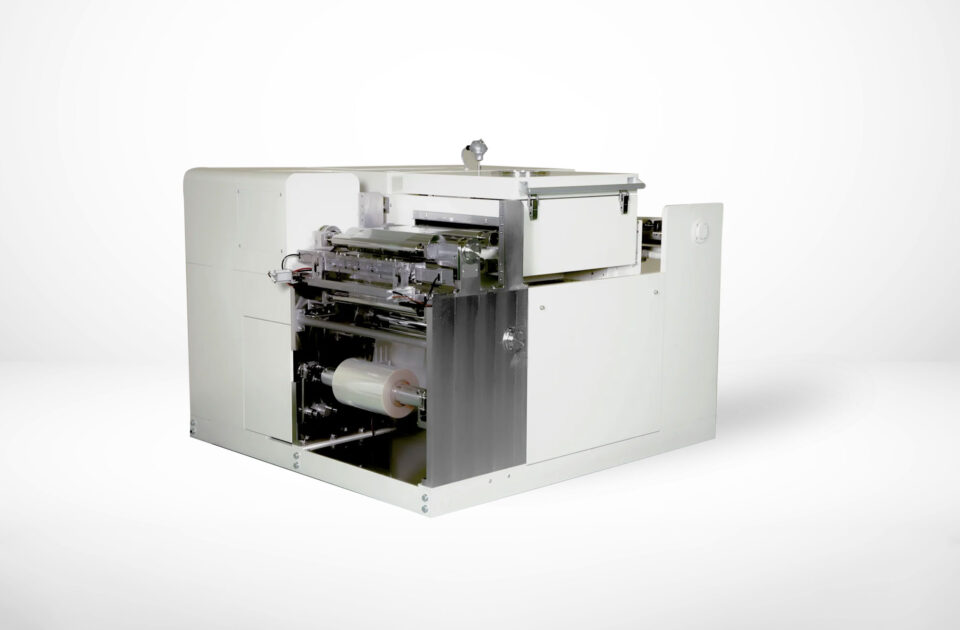

Coating Machines

Coating machines are used to impart functionality to films. The coating method varies depending on the type of substrate and liquid used.

With accumulated expertise and technology, we propose suitable coating methods.

修正-960x600.png)

Coating methods vary greatly depending on the substrates and liquid!

Our accumulated expertise and technology allow us to propose the optimal method for you!

-

Coating methods are diverse

A variety of combinations exist, as substrates can be uneven, prone to absorption, or repellent, and types of liquid vary from aqueous to clay-like or adhesive.

Determining the coating method involves appropriate proposals based on experience and simulations, along with demonstrations using prototype machines.

We collaborate closely with customers to develop machines, mainly through testing at our Technical Center. -

Thinner, more uniform coatings

Liquid crystal films, such as those used in smartphones, are coated with ultra-thin functional materials. This provides various functions like fingerprint resistance and reduced visibility from angles.

These coatings are at the nanometer level, and demand for thin film coatings will continue to grow.

-

Thicker coatings, uniform drying

Traditional techniques for thick coatings are widely used in everyday items like artificial leather and carpet backing.

In recent years, thick film coating technology is being applied to electronic materials.

This includes laminated ceramic capacitors, electrodes for lithium-ion secondary batteries, and printed circuit boards.

Our extensive experience is particularly beneficial in achieving uniform drying of thick materials. -

Fully customized

We manufacture machines completely tailored to your needs, realizing even the smallest and most complex requests, creating "one-of-a-kind machine" for you.

Our approach is also highly acclaimed by universities and corporate research laboratories.

Applications & Features

- Applications

-

- General purpose films

- Optical films

- Electronic material films

- Ion exchange membranes

- Features

-

- Various coating methods

- Uniform drying methods with high-precision temperature and wind speed control

- Transporting methods according to characteristics of substrates

.gif)

修正3.gif)

修正.gif)

修正2.gif)

.gif)

修正-960x600.png)

-960x600.png)

-960x600.png)

-1-960x600.png)